WJE PROJECTS

Claus Waste Heat Boiler

CLIENT |

Confidential |

LOCATION |

Midwest, United States |

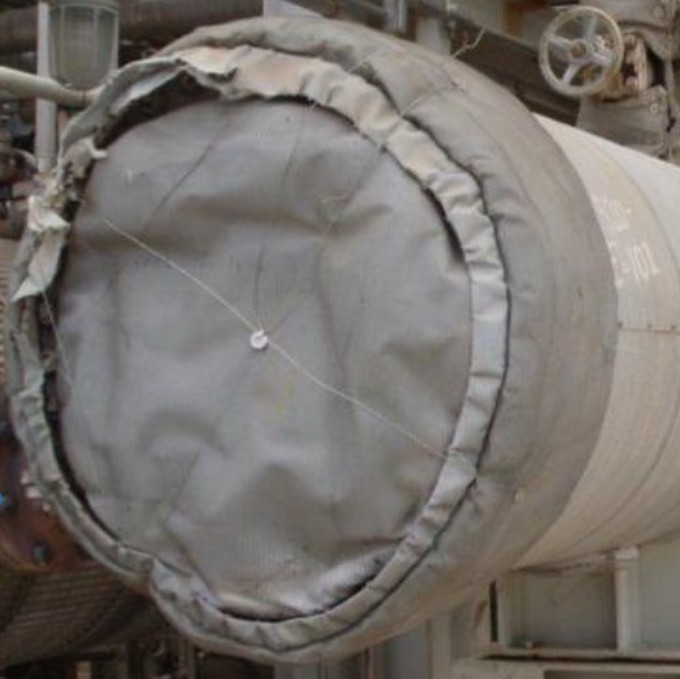

Engineering Evaluation of a Mechanical Clamp Repair

WJE was asked to perform engineering calculations to establish minimum allowable thickness values for the major components comprising the boiler outlet channel. Accelerated short-term corrosion rates, likely due to temperature excursions during operation, were identified with periodic monitoring. The objective of the effort was to provide inspection guidance and acceptance criteria as wall thinning occurred and to verify an engineered ASME PCC-2 mechanical clamp design installed to extend the useful life of the outlet channel.

BACKGROUND

The Claus Waste Heat Boiler is a heat transfer vessel installed in a Sulphur Recovery Unit, which has several unique damage mechanisms related to elevated operating temperatures exceeding 650°F. The boiler was constructed according to ASME Boiler and Pressure Vessel Code Section I. The 2-foot Inner Diameter (ID) by 2-foot-7.5-inch-long boiler channel was constructed from SA-516 Grade 70 carbon steel, with a nominal shell thickness of 3/8 inch and a corrosion allowance of 1/8 inch. The outlet channel has a large, 8-inch nozzle and a flat bolted cover.

SOLUTION

WJE performed a fitness for service (FFS) evaluation based on API 579-1/ASME FFS-1, Part 4, Assessment of General Metal Loss, and Part 10, Assessment of Components Operating in the Creep Range, to establish mechanical integrity of the outlet channel. Failure modes considered in the evaluation included plastic collapse, gasket sealing at the bolted cover, and degradation of the carbon steel strength and ductility.

The assessment used a Level 1 methodology to determine minimum allowable thickness values for the outlet channel shell, 8-inch nozzle, and bolted flat cover components. Furthermore, the remaining life of the components was predicted based on short- and long-term corrosion rates to provide guidance on inspection intervals and other mitigation methods.

The FFS assessment demonstrated that, if cooling steam was applied to reduce the overall temperature, the Claus Waste Heat Boiler had sufficient remaining strength to satisfy the minimum required design margins for in-service equipment for a finite but limited period of time. This allowed the owner/operator to efficiently plan for installation of an engineered mechanical clamp to temporarily restore the strength of the pressure boundary until in-kind replacement could be undertaken.

RELATED INFORMATION

-

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy -

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

WJE fracture mechanics consultants have provided fracture mechanics assessment and fitness for... MORE >Services | Fracture Mechanics Assessment and Fitness for Service

WJE fracture mechanics consultants have provided fracture mechanics assessment and fitness for... MORE >Services | Fracture Mechanics Assessment and Fitness for Service