Most metallurgical failures can be traced back to either inadequate design or materials quality. Understanding materials behavior—from welding and brazing to corrosion and other forms of degradation—and a component’s response to complex loading is paramount to determining why a part or component failed and to preventing failures in new designs. Clients rely on the extensive experience of our metallurgical and applied mechanics engineers to provide engineering solutions related to design optimization and evaluation of in-service failures.

Our metallurgical and applied mechanics engineers leverage extensive knowledge of materials behavior and failure modes in conjunction with recognized industry analysis techniques to understand structural response to complex mechanical and thermal loading and to evaluate in-service damage mechanisms. We possess decades of experience in the evaluation of all types of materials, parts, and components and can provide cost-effective solutions for challenging designs, existing infrastructure, and mitigation of unexpected failures.

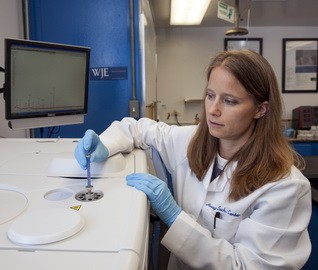

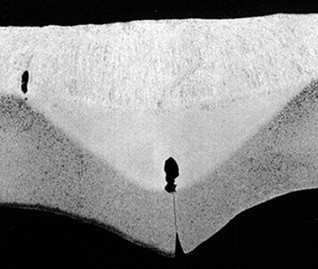

Our state-of-the-art Janney Technical Center laboratories are equipped to handle a wide variety of materials characterization and testing, including composition and microstructure. Among other advanced testing equipment, our scanning electron microscope is an invaluable tool in the investigation and analysis of part and component failures. But our capabilities are not confined to the laboratory. We routinely employ a diverse array of nondestructive evaluation capabilities in the field, including ultrasonic testing, magnetic particle testing, thermography, and field metallography and replication.

- Metallurgical consulting and testing

- Metals characterization

- Forensic investigations

- Metallurgical failure analysis

- Downstream and process industries

- Upstream oil and gas

- Weld engineering

- Corrosion assessment

- Heat treating evaluations

- Fire damage assessment

- Litigation consulting

- Mechanical testing

- Metal fatigue and fracture

- Fracture mechanics assessment and fitness for service

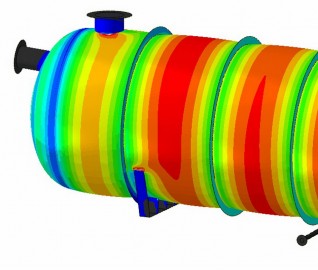

- Nonlinear finite element analysis

- Materials and analytical modeling

- Peer review

- Metallography

- WJE CrackCalc™ (API 579 Fracture Mechanics Software)

RELATED INFORMATION

-

Bernard J. Schulze, Principal and Unit ManagerWJE Northbrook MORE >People | Bernard J. Schulze, Principal and Unit Manager

Bernard J. Schulze, Principal and Unit ManagerWJE Northbrook MORE >People | Bernard J. Schulze, Principal and Unit Manager -

After several large concrete spalls fell from a catalytic reformer support structure at a... MORE >Articles | Asset Integrity Case Study: Catalytic Reformer Support Structure

After several large concrete spalls fell from a catalytic reformer support structure at a... MORE >Articles | Asset Integrity Case Study: Catalytic Reformer Support Structure -

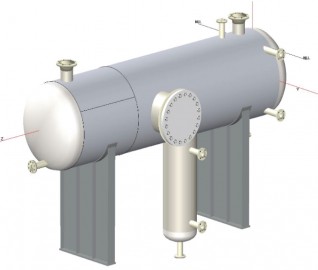

Engineering Evaluation of a Mechanical Clamp Repair MORE >Projects | Claus Waste Heat Boiler

Engineering Evaluation of a Mechanical Clamp Repair MORE >Projects | Claus Waste Heat Boiler -

Developed in-house, WJE CrackCalc™ is a software package that provides users the ability to... MORE >Services | WJE CrackCalc™

Developed in-house, WJE CrackCalc™ is a software package that provides users the ability to... MORE >Services | WJE CrackCalc™ -

API 579-1 Fitness for Service Assessment of Local Thinning MORE >Projects | Flare Knockout Drum

API 579-1 Fitness for Service Assessment of Local Thinning MORE >Projects | Flare Knockout Drum -

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy -

Design Calculations to Support NBIC Alterations MORE >Projects | Pressure Vessel Design Rerates

Design Calculations to Support NBIC Alterations MORE >Projects | Pressure Vessel Design Rerates -

WJE routinely assists in failure analyses relating to incorrect or unintentional heat treatments... MORE >Services | Heat Treating Evaluations

WJE routinely assists in failure analyses relating to incorrect or unintentional heat treatments... MORE >Services | Heat Treating Evaluations