It is just a fact of life that pipe and circular tube are never perfectly round, nor do they have a perfectly uniform thickness around the circumference, nor are they perfectly straight along their length, and nor can perfect fitup at a weld be achieved. It is intuitive that we have to live with some imperfection, but determining what should be and how best to arrive at the optimal outcome is not always straightforward.

In this article, engineers and welding experts Steven Altstadt and Robert Warke cover common causes of misalignment in circumferential welds, mitigation options, and strategies industries use to determine their respective allowable limits.

This article originally appeared in the May 2021 issue of Welding Journal, the official publication of the American Welding Society that has been published continually since 1922.

RELATED INFORMATION

-

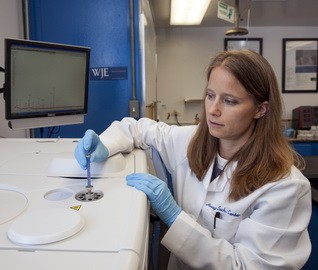

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing -

Robert W. Warke, Associate PrincipalWJE Northbrook MORE >People | Robert W. Warke, Associate Principal

Robert W. Warke, Associate PrincipalWJE Northbrook MORE >People | Robert W. Warke, Associate Principal -

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy