EXPERTISE // SERVICES // METALLURGY AND APPLIED MECHANICS

Downstream and Process Industries

With nearly a half century of experience in industrial consulting, we are no stranger to the unique challenges posed by the process and refining industries. Our dedicated team of metallurgical and applied mechanics engineers have the tools and expertise needed to solve the biggest problems in the pressurized world. We offer full-service chemical and metallurgical laboratories, knowledgeable experts in process, corrosion, and pressure equipment experts that can rapidly assess aging equipment. We also offer pressure vessel design services, including high-pressure designs.

Our principal areas of practice include fitness for service assessments (API 579 / ASME FFS-1), pressure vessel design and rerates, piping design and analysis, fire damage and extreme event evaluations, failure analysis and root cause analysis, nonlinear finite element analysis, inspection planning and turnaround support, material testing and analytical modeling, high temperature applications, and weld design and qualification.

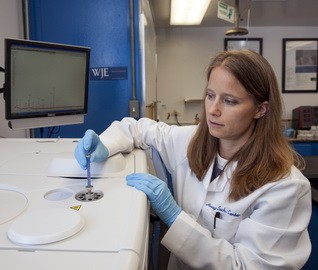

Our deep expertise in the process industry expertise is supported by a multidisciplinary structures team to assist owner/operators with challenges related to the interaction of fixed equipment with its surrounding structural supports or foundations. Our in-house, advanced, state-of-art metallurgical and materials laboratories are equipped to handle a wide variety of materials characterization and testing, including composition and microstructure.

We are committed to utilizing our industrial experience to help clients solve, repair, and avoid problems in both the pressurized and built worlds.

- Fitness for Service Assessments (API 579)

- Pressure Vessel Design and Rerates

- Piping Design and Analysis

- Fire Damage and Extreme Event Evaluations

- Failure Analysis and Root Cause Analysis

- Nonlinear Finite Element Analysis

- Corrosion assessment

- Turnaround Support and Inspection Planning

- Material Testing and Analytical Modeling

- Service life modeling

- High Temperature Applications

- Weld Design and Qualification

- WJE CrackCalc™ (API 579 Fracture Mechanics Software)

RELATED INFORMATION

-

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy -

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center