EXPERTISE // SERVICES // METALLURGY AND APPLIED MECHANICS

Corrosion Analysis

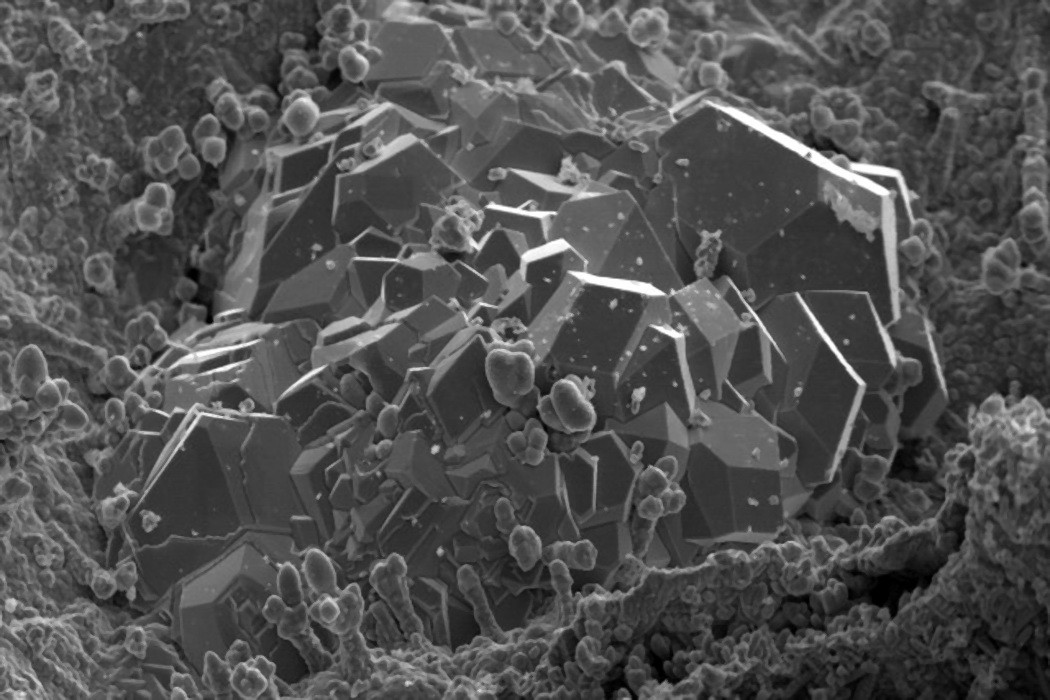

The global cost of corrosion expenses is in the billions, and component failures because of corrosion can be catastrophic. We combine experience, technology, and lessons learned from numerous metal corrosion investigations to address the root cause of the degradation and to improve the overall performance of the system. The process usually starts with assessing the corroded components or products to identify specific factors that may be catalyzing the corrosion. Corrosion is the wastage or degradation of a metal due to environmental exposure, which can lead to a loss of its desired mechanical properties or failure. At an atomic level, corrosion is caused by an electrochemical reaction of the metal to its environment, ultimately causing the metal to deteriorate.

In general, corrosion is undesired whether it’s a major or minor situation. It is always important to determine the root cause(s) of corrosion, as it’s usually not just one factor but rather a combination of the susceptibility of materials and their environmental conditions (such as contamination by deleterious chemical species).

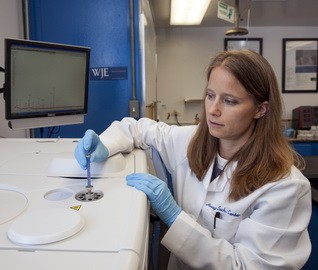

The metallurgy and applied mechanics engineers in our Janney Technical Center (JTC) laboratory have the analytical tools and experience to understand and diagnose the causes of metallic corrosion. There are environments and applications where corrosion cannot be avoided—in hazardous environments such as chemical processing plants or where using a more corrosion-resistant material is not feasible. In these cases, corrosion should be considered when designing or repairing a component. Laboratory and field corrosion tests provide data and insight for the selection of metals that will determine the acceptable and manageable performance of an application. The JTC offers environmental chambers and rooms for accelerated corrosion testing with equipment and laboratories for customized corrosion and exposure testing. Our metallurgists provide high-quality expertise and laboratory capabilities to resolve difficult corrosion challenges that clients encounter across many industries.

- Component testing

- Corrosion Assessment and Service Life Evaluation (WJE CASLE™)

- Documentation of existing conditions and scope of damage

- Estimation of remaining service life

- Estimation of remaining strength and ductility

- Failure analysis and root cause analysis

- Fracture mechanics assessment and fitness for service

- Laboratory and field testing of materials

- Metallurgy and applied mechanics

- Repair and retrofit design

- Visual survey and condition assessment

RELATED INFORMATION

-

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

WJE is a leader in durability assessment services for reinforced concrete structures MORE >Services | Corrosion Assessment and Service Life Evaluation (WJE CASLE™)

WJE is a leader in durability assessment services for reinforced concrete structures MORE >Services | Corrosion Assessment and Service Life Evaluation (WJE CASLE™) -

Elise Love explores a phenomenon known as galvanic corrosion in this WJE primer. MORE >Articles | WJE Primer: Galvanic Corrosion

Elise Love explores a phenomenon known as galvanic corrosion in this WJE primer. MORE >Articles | WJE Primer: Galvanic Corrosion -

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center