WJE PROJECTS

Roosevelt University Auditorium Building

CLIENT |

Roosevelt University |

LOCATION |

Chicago, IL |

Roof and Facade Access Enhancements

In 2016, the Occupational Safety and Health Administration (OSHA) issued a final rule updating the fall protection requirements of the General Industry Walking-Working Surfaces standard. The new regulations require building owners to provide certified anchorage points for workers using rope descent systems (RDS)—commonly referred to as boatswain’s chairs—for window washing. WJE designed new dedicated facade access equipment and certified the equipment by load testing to the minimum OSHA-specified design load.

BACKGROUND

Constructed between 1887 and 1890, the Auditorium Building was designed by Dankmar Adler and Louis Sullivan. The Auditorium Building currently serves the academic and administrative functions of Roosevelt University. The building is a steel-framed structure with massive load-bearing exterior masonry walls. The building is ten stories tall and is U-shaped in plan. A tower is present near the center of the south facade and extends seven stories above the main roof level. The Auditorium Theatre is located at the center of the building filling in the U-shape. The Auditorium Building and Theatre are National Historic Landmarks.

SOLUTION

To provide OSHA-compliant facade access and fall protection at the Roosevelt University Auditorium Building, WJE performed the following services:

- Documented existing conditions, investigated approaches, and developed compliance strategies for roof and facade access

- Designed and prepared construction documents for new dedicated equipment, including masonry pilaster-mounted frames, masonry wall anchorages, steel beam anchorages, and smoke shaft guardrails

- Performed mockups and construction period services during installation of the new equipment

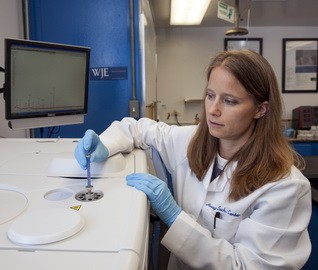

- Developed a testing protocol, designed a custom test frame, and load tested the new equipment

- Prepared a report and roof access plan summarizing the facade access equipment, load test results, and equipment inspection and maintenance requirements

Each anchorage point was loaded in a manner that replicated the minimum design load (i.e., 5,000 pounds) required by OSHA and the Chicago Building Code in potential directions of use. The new equipment sustained the test load in an appropriately elastic manner and was certified for use.

RELATED INFORMATION

-

We provide clients with accurate, actionable answers through a spectrum of in situ load testing... MORE >Services | Structural Load Testing

We provide clients with accurate, actionable answers through a spectrum of in situ load testing... MORE >Services | Structural Load Testing -

We engage a full suite of state-of-the-art instrumentation and monitoring capabilities to test... MORE >Services | Instrumentation and Monitoring

We engage a full suite of state-of-the-art instrumentation and monitoring capabilities to test... MORE >Services | Instrumentation and Monitoring -

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering -

We apply the lessons learned from more than 175,000 projects to provide clients with a full... MORE >Services | Condition Evaluation

We apply the lessons learned from more than 175,000 projects to provide clients with a full... MORE >Services | Condition Evaluation