WJE PROJECTS

Crystal Square 5

CLIENT |

Vornado/Charles E. Smith |

LOCATION |

Arlington, VA |

Facade Evaluation and Restoration

The client contacted WJE to assist with the recoating of the building exterior. The metal panels at the building were originally designed as a drained assembly that permit water to enter behind the cladding that is then managed through weeps and flashing to the exterior. The metal panels had been converted to a barrier assembly with the addition of exterior, preformed silicone bridge seals at the perimeter of all the metal panels. The seals were to be removed and replaced as part of the facade coating project.

BACKGROUND

Constructed in 1973, Crystal Square 5 is a thirteen-story structure that is rectangular in plan and includes plaza-level retail space, offices, and an upper-level penthouse/mechanical space. The building facade primarily consists of metal panels and nonthermally improved aluminum punched windows, with louvers along the perimeter of the penthouse level.

SOLUTION

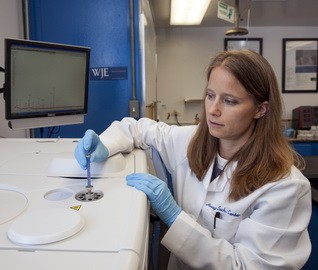

WJE completed a limited visual condition assessment of the exterior metal panels and joint sealant. To document prior repairs and problem areas, we reviewed the metal panels, window assemblies, and joint sealant, in addition to the ground-level storefronts and soffits. During the exterior survey, we also completed adhesion testing of the existing coating on the metal facade panels in accordance with ASTM D3359 and ASTM D4541. We collected coating samples for our in-house laboratory to evaluate the composition and coating types of each sample. The testing results informed contract documents pertaining to joint sealants and high-performance coatings, which were incorporated into a subsequent facade restoration project. We helped the architect of record further refine the full-scale restoration program based on a trial repair of coating removal and installation. We also provided construction period services throughout the implementation of the repairs.

In conjunction with the coating and sealant replacement, we assisted the owner by documenting evidence of interior water penetration. We completed water penetration testing to identify water entry points, developed repairs, and water tested repairs to confirm the leakage was addressed.

RELATED INFORMATION

-

We apply the lessons learned from more than 175,000 projects to provide clients with a full... MORE >Services | Condition Evaluation

We apply the lessons learned from more than 175,000 projects to provide clients with a full... MORE >Services | Condition Evaluation -

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation -

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing -

Learn about our Washington, D.C. office MORE >Offices | Washington, D.C.

Learn about our Washington, D.C. office MORE >Offices | Washington, D.C.