WJE PROJECTS

55 West Monroe

CLIENT |

Manulife Investment Management |

LOCATION |

Chicago, IL |

Facade Access Anchorages

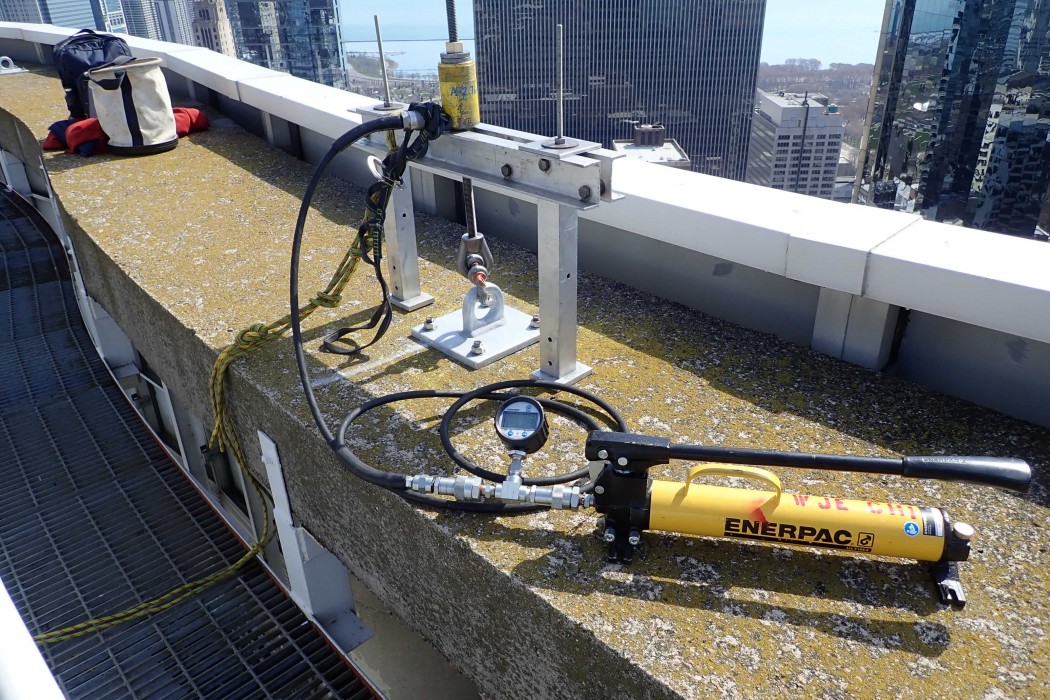

In light of the updated OSHA regulations, WJE load tested the original davits and davit bases at the building to support facade access activities. During testing, several of the davit bases failed to support the OSHA-required loads for use with davits. Corrosion of the steel components of the davit bases appeared to be a contributing factor to their failure. Since replacing the davit bases would have triggered costly OSHA upgrades, the owner elected to replace the existing davit system with a less complicated anchorage system.

BACKGROUND

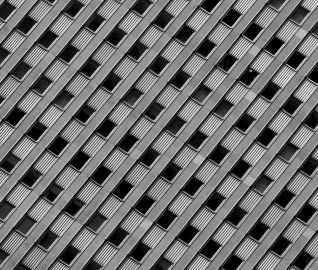

The 55 West Monroe building, constructed circa 1977, is a forty-one-story, 473-foot-tall reinforced concrete structure, clad with an aluminum and glass curtain wall. The building is rectangular in plan with a rounded facade at the northeast corner. The roof construction consists of an eight-inch-thick, two-way, reinforced concrete flat slab that is supported by concrete columns.

In 2016, Occupational Safety and Health Administration (OSHA) issued a final rule updating the fall protection requirements of the General Industry Walking-Working Surfaces standard. The new regulations prohibit the use of rope descent systems (RDS) on buildings that are greater than 300 feet tall.

SOLUTION

WJE designed new dedicated anchorages for use with industrial rope access (IRA) for routine maintenance and for ground-rigged, contractor-provided swing stages for construction-related work. To provide OSHA-compliant facade access at the 55 West Monroe building, WJE performed the following services:

- Documented existing conditions to determine an effective layout for new anchorages

- Designed and prepared construction documents for new anchorages.

- Coordinated roofing repairs with the previous roof installer to maintain the roofing warranty

- Performed construction-period services during installation

- Developed a testing protocol and load tested the new anchorages

- Prepared a report summarizing methods of facade access, results of load testing, and requirements for equipment use and periodic inspections

Each anchorage was loaded in a manner that replicated the minimum strength (i.e. 5,000 pounds) required by OSHA and the Chicago Building Code in potential directions of use. All anchorages supported the test load without any significant permanent deformation or failure. Based on our test results, WJE concluded that each certified anchorage is suitable for securing a single fall arrest lifeline or equipment tieback wire rope for facade access using IRA or contractor-provided suspension equipment.

RELATED INFORMATION

-

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering -

We provide clients with accurate, actionable answers through a spectrum of in situ load testing... MORE >Services | Structural Load Testing

We provide clients with accurate, actionable answers through a spectrum of in situ load testing... MORE >Services | Structural Load Testing -

Our building science expertise and resources are the result of a commitment to understanding the... MORE >Services | Building Science

Our building science expertise and resources are the result of a commitment to understanding the... MORE >Services | Building Science -

We understand the myriad challenges faced by building owners and managers, and we're committed... MORE >Markets | Buildings

We understand the myriad challenges faced by building owners and managers, and we're committed... MORE >Markets | Buildings