This specification covers chemical admixtures to be added to hydraulic cement concrete mixtures for use in producing flowing concrete. The two types of chemical admixtures are: Type I–plasticizing; and Type II–plasticizing and retarding. Tests of the chemical admixtures with reference concreting materials or with concrete-making materials proposed for specific work are specified. Three levels of testing are discussed: Level 1, Level 2, and Level 3. Types of admixtures shall conform to the physical requirements: time of setting, increase in slump, compressive strength, flexural strength, length of change after days of drying, and relative durability factor. Uniformity and equivalence shall be established by the following requirements: infrared analysis, residue by oven drying (liquid and nonliquid admixtures), and specific gravity (liquid admixtures). Tests for quality, uniformity, and equivalence shall be made. Samples of freshly mixed concrete shall be tested according to slump, air content, time of setting, and water content and unit weight. Hardened concrete shall be tested according to the following: compressive strength, flexural strength, resistance to freezing and thawing, and length change.

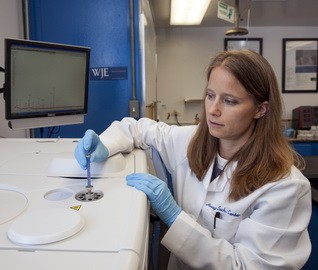

WJE laboratories are accredited by ANAB (ISO/IEC 17025) to perform testing standard ASTM C1017 for Chemical Admixtures for Use in Producing Flowing Concrete.

Contact us to learn more.

Keywords

ASTM C1017 - Chemical Admixtures - Concrete - Hydraulic Cement - Plasticizing Admixtures - Retarding Admixtures - Set-Retarding Admixtures - Water-Reducing Admixtures

ICS CODE

91.100.30 (Concrete and concrete products)

UNSPSC CODE

30111500 (Concrete and mortars)

CITATION FORMAT

ASTM C1017 / C1017M-13e1, Standard Specification for Chemical Admixtures for Use in Producing Flowing Concrete, ASTM International, West Conshohocken, PA, 2013,

www.astm.org

John E. Pearson, Principal and Laboratory ManagerWJE Northbrook MORE >People | John E. Pearson, Principal and Laboratory Manager

John E. Pearson, Principal and Laboratory ManagerWJE Northbrook MORE >People | John E. Pearson, Principal and Laboratory Manager WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing WJE was founded on a spirit of innovation—that everything can be improved and that... MORE >Services | Product Development, Evaluation, and Testing

WJE was founded on a spirit of innovation—that everything can be improved and that... MORE >Services | Product Development, Evaluation, and Testing